Hard work is a given in many industries, but it also comes with its risks, especially concerning hand injuries. The Occupational Safety and Health Administration (OSHA) recognizes this and has set specific standards for hand protection. Amid these standards, nitrile gloves emerge as a practical solution, offering protection without compromising performance.

Understanding OSHA's Hand Protection Standards

The Occupational Safety and Health Administration (OSHA) ensures safe and healthy working conditions across various industries. One of their key focus areas is hand protection, where they have established detailed guidelines to mitigate the risk of hand injuries in the workplace. These guidelines are not merely suggestions but enforceable standards that employers must adhere to for the welfare of their employees.

Hand injuries are among the most common workplace injuries. According to data from the Bureau of Labor Statistics, thousands of workers suffer from debilitating hand injuries every year, which can be avoided with proper safety measures. Hands are vital tools in most jobs and are exposed to various hazards. These hazards range from cuts and burns to long-term damage from chemicals or extreme temperatures.

Scope of OSHA's Hand Protection Regulations

OSHA's regulations (under Standard 29 CFR 1910.138) specifically state that employers must select and require employees to use appropriate hand protection when their hands are exposed to hazards. These hazards are broadly categorized as:

- Exposure to Harmful Substances: This includes handling chemicals, biohazards, and other hazardous materials that can cause skin irritation, absorption of harmful substances, or chemical burns.

- Severe Cuts or Lacerations and Abrasions: Often encountered in industries involving machinery, tools, or sharp materials.

- Punctures: Risks prevalent in environments where sharp objects such as nails, wires, or needles are handled.

- Chemical and Thermal Burns: This covers exposure to hot surfaces, molten materials, and chemical reactions that can cause burns.

- Extreme Temperatures: Protecting hands from extreme cold or heat, which can cause frostbite or burns and affect manual dexterity.

Compliance and Selection of Protective Equipment

To comply with OSHA standards, employers must provide hand protection and ensure that the protection is adequate for the specific hazards present in their workplace. This involves assessing the workplace for potential hand injury risks and choosing gloves and other hand protection equipment based on factors like material, durability, flexibility, and resistance to chemicals, cuts, and temperatures.

For example, in a chemical laboratory, gloves that provide chemical resistance would be essential, whereas, in a construction setting, gloves with cut and puncture resistance would be more appropriate. It's not just about providing gloves; it's about providing the right kind of gloves for the specific task.

The Cost of Non-Compliance

Non-compliance with these standards can lead to severe repercussions for companies. OSHA is empowered to conduct inspections and can impose penalties for violations. These penalties vary depending on the nature of the violation:

- Serious Violations: If there is a substantial probability that death or serious physical harm could result from a hazard the employer knew or should have known, it's classified as a serious violation. Fines for serious violations can be substantial, often amounting to tens of thousands of dollars per violation.

- Willful or Repeated Violations: Penalties for willful or repeated violations are even more severe, potentially reaching hundreds of thousands of dollars per violation. A willful violation occurs when an employer knowingly fails to comply with a legal requirement or acts with indifference to employee safety. Repeated violations indicate a pattern of non-compliance.

- Failure to Abate Prior Violation: If an employer fails to remedy a previously cited violation, they can be charged daily penalties until the situation is resolved.

Impact on Insurance and Liability

Beyond OSHA penalties, non-compliance can significantly impact a company's insurance and liability. Workplace injuries often lead to increased workers' compensation insurance premiums. A history of non-compliance and workplace injuries can make a company a higher risk, leading to higher insurance costs.

Moreover, non-compliance can expose companies to legal liabilities. In cases where it's evident that an employer neglected their duty to provide proper hand protection, they may face lawsuits from injured employees. These lawsuits can result in settlements or judgments that far exceed the cost of compliance.

Enhanced Company Reputation and Morale

Conversely, adhering to OSHA's hand protection standards can enhance a company's reputation. Companies known for their commitment to safety are often viewed more favorably by potential clients, partners, and employees. This commitment can lead to more business opportunities and a more dedicated workforce. Furthermore, a safe work environment increases employee morale and productivity, as they feel valued and protected.

Understanding and adhering to OSHA's hand protection standards is crucial for companies across various industries. It's not only a matter of compliance but also a vital aspect of workforce safety, financial stability, and overall company reputation. The potential penalties and insurance implications make it clear that investing in proper hand protection, such as nitrile gloves, is a wise and necessary decision for companies looking to thrive.

The Risks Faced in Various Work Environments

Various work environments present a myriad of hand injury risks, ranging from the dangers posed by sharp objects and abrasive surfaces to the threats of chemical exposure. Workers engaged in various tasks are in constant need of robust hand protection. Recognizing these hazards, OSHA standards necessitate using gloves specifically designed to counteract the risks associated with each type of task.

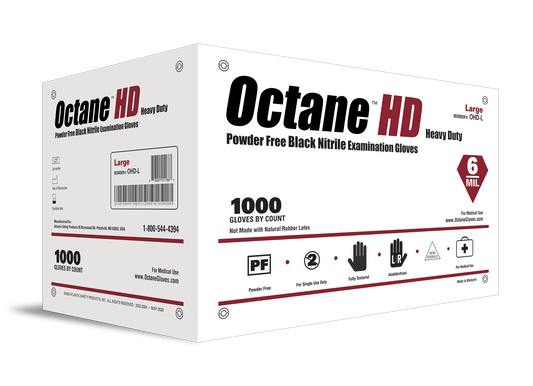

Nitrile gloves emerge as a particularly effective solution in this context. They excel in the essential areas of chemical resistance, durability, and puncture resistance, making them suitable for a wide range of activities across industries. Unlike their latex or vinyl counterparts, nitrile gloves provide enhanced protection, aptly meeting the demanding conditions commonly found in various work settings. Their robust material properties protect workers' hands from the diverse hazards they face on the job.

However, the mere provision of nitrile gloves isn't enough. For them to be truly effective in safeguarding workers, selecting the appropriate type of nitrile glove is crucial. This selection should be guided by various factors, such as the gloves' thickness, length, and grip, which should align with the specific requirements of different tasks. Moreover, it's imperative to educate workers about the correct usage of these gloves. Proper training ensures that nitrile gloves are integrated effectively into daily safety practices, maximizing their potential to prevent hand injuries.

Overcoming Barriers to Compliance

Compliance with safety standards, particularly regarding hand protection, can face several barriers. A primary concern often voiced by workers is the loss of dexterity when wearing gloves. This concern is crucial, as many tasks require precise hand movements and a firm grip. However, advancements in glove technology have led to the development of modern nitrile gloves, which are designed to address this issue effectively. These gloves offer flexibility and a snug fit, allowing for more precise hand movements and a better grip. The material used in nitrile gloves is thin enough to allow for tactile sensitivity yet durable and resistant enough to provide adequate protection.

Another aspect that often hinders compliance is the perception of the cost of high-quality gloves. While it's true that nitrile gloves can be more expensive than other types of hand protection, the investment is justifiable, especially when considering the long-term benefits. High-quality nitrile gloves tend to be more durable and offer better protection, which can reduce the frequency of replacements. Additionally, investing in proper hand protection can significantly reduce the incidence of workplace injuries, leading to lower costs related to workers' compensation, medical expenses, and potential OSHA penalties for non-compliance.

Moreover, educating workers about the importance of hand protection and the specific advantages of using nitrile gloves can significantly aid in overcoming resistance to glove use. Training programs can demonstrate how to use and maintain these gloves, enhancing their effectiveness and lifespan. Employers can also engage workers in the selection process, allowing them to choose gloves that best fit their needs, which can increase acceptance and usage. By addressing the concerns about dexterity, cost, and awareness, employers can effectively overcome barriers to compliance and foster a safer and more compliant workplace.

Conclusion

Nitrile gloves are more than just a compliance requirement; they are a key element in a comprehensive safety strategy across various industries. As companies strive to meet and exceed OSHA standards, adopting nitrile gloves is a step in the right direction. For those looking to enhance their safety gear, exploring the options in nitrile gloves is a recommended starting point.